NIKO C2 light cranes are the ideal solution for lightweight lifting of load capacities up to 2000kg. They are supplied in a modular kit form, which enables them to be easily assembled, modified or moved to accommodate changes in your working patterns. The construction of NIKO C2 light cranes is considerably lighter, free-running and more versatile than conventional l-beam overhead cranes.

KEY FEATURES

- Lift loads up to 2000kg

- Bridge span up to 12m

- Smooth and easy movement in all directions

- Manual or electronic lifting and travel

- Robust construction

- Wide range of fixing brackets

- Zinc plated, powder coated, hot dip galvanised finish

- Available in Stainless steel

- Modular design

CEILING MOUNTED LIGHT CRANES

Ceiling mounted light cranes are an ideal solution for applications where floor space is at a premium. The light crane can be suspended directly or dropped down from the existing ceiling or building support beams. The NIKO C2 range has a wide variety of suspension brackets to enable the light crane to be suspended from virtually any roof structure. The major advantage of this type of system is that the floor space is kept clear of supporting stanchions, enabling free movement underneath the light crane.

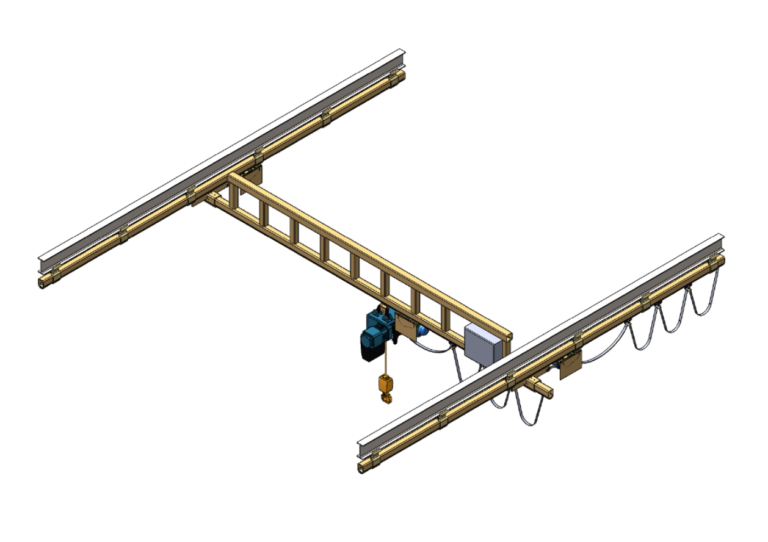

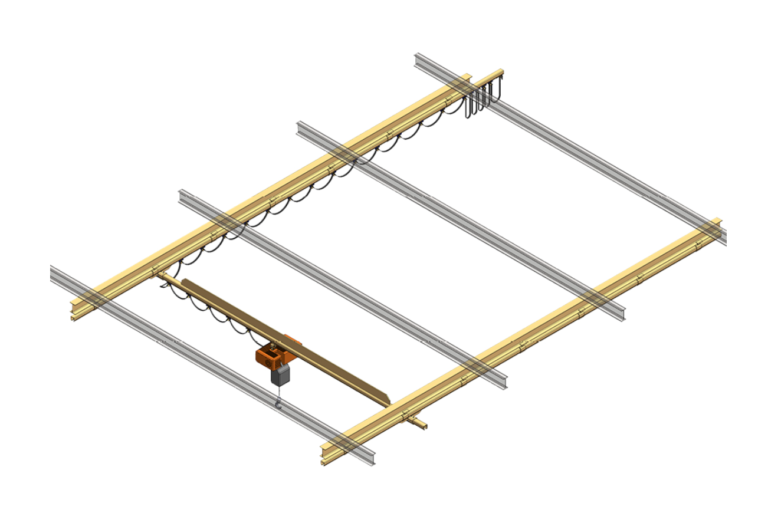

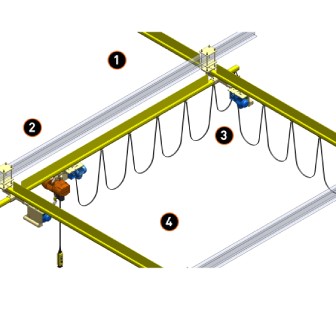

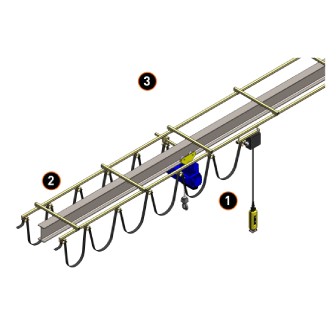

Light cranes usually comprise of 2 runway tracks running parallel with a bridge suspended below. The bridge enables a chain hoist or alternative lifting device to be suspended and travel from side to side along the bridge. The bridge can be travelled forwards and backwards along the runway tracks. This enables to operator to lift, move and lower a load anywhere within the working footprint below the light crane. It is possible to have multiple light crane bridges suspended from the same runway tracks.

SINGLE GIRDER LIGHT CRANES

Single-girder light cranes feature a single-track bridge rail. This is the most common type of light crane system. The main advantage of single-girder light cranes is that they offer the widest travel distance along the bridge and across the runway tracks.

DOUBLE GIRDER LIGHT CRANES

Double girder light cranes feature a twin track bridge rail with the hoist suspended so that the weight of the load is carried evenly across both rails. The main advantage of double girder light cranes is that they offer a wider span between the runways than a single girder equivalent. It is also possible to add an intermediate runway beam and enable an even longer bridge length.

LOW-HEADROOM LIGHT CRANES

Low-headroom light cranes feature a double girder bridge with a raised suspension section for mounting the hoist or alternative lifting device. The NIKO product offers the lowest available headroom solution on the market. As a standard, the hoist is suspended within 100mm of the crane support point and in some instances even less. The main advantage of Low-headroom light cranes is that they provide a lifting solution in confined spaces where overhead lifting would not normally be possible.

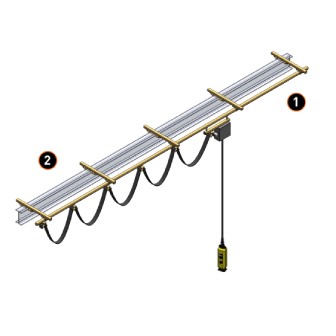

MONORAILS

Monorails feature an independent track rail with a trolley that can be used to suspend a hoist or alternative lifting device. The hoist can then travel forward and back along the full length of the rail. Monorails consist of an assembly of straight track sections, curved track bends, junction switches, and turn tables. The junction switches and turn table enable a change in direction, allowing the hoist trolley to follow different travel paths.

LIGHT CRANE LATCHING SYSTEMS

Latching systems interlock with the bridge of a light crane and enable the hoist trolley to be used on an adjacent monorail or another light crane system. It is possible to combine multiple latching devices within a single light crane system. The main advantage of latching systems is that they enable the use of the hoist or alternative lifting device outside of the normal working footprint of a light crane.

SLIDING CANTILEVER BEAMS

Sliding cantilever beams are used to enable lifting outside of the normal working footprint of a light crane or monorail system. They feature an under-slung cantilever section suspended from a light crane bridge, monorail track or crane runway rails. The cantilever section can then travel past the confines of the suspending rail and enable lifting outside of the normal lifting footprint. This type of system is the ideal solution for lifting and moving a load in and out of containers; or for cranes that need to avoid obstacles within the working area.

FREESTANDING BRIDGE CRANES

Freestanding light cranes are generally used when the ceiling is not strong enough to support the weight of the crane and the load. The crane is supported by a freestanding steel work support structure, which is designed and fabricated to suit the requirements of the working area. The support structure usually bolts directly to the floor, but can also be partially suspended from adjacent walls, stanchions, or overhanging beams.

Advantages:

- Ultra-low headroom

- Crane bridge does not grab

- Low-maintenance and long working life

- Easy to install

- Fit directly to roof and a wide range of structures

- For indoor and outdoor applications

- Ideal for food applications and clean areas

- Easy to extend, modify or relocate

- Can connect to other cranes and conveyors

- Cost effective

JIB CRANES

NIKO Ltd manufactures and supplies a wide range of different types of jib cranes, that can be freestanding, clamp around an existing column or bolt directly to a wall. Comprising various arm types, NIKO jib cranes are built to customer requirements to ensure they fully satisfy the customers lifting requirements.

Features

- SWL: 25 – 2000kg

- Arm length: up to 6m

- Column height: up to 6m

- Arm types: profile track, under-braced I-beam, over-braced I-beam, and articulated/knuckle

- Fixing: freestanding, wall fixing, clamp around/column fixing

- Slewing arc: 270°on standard arms or 360° on articulated arms

- Finish: powder coated, hot dip galvanized or stainless steel

- Designed in accordance with BS 7333: 1990

Advantages

- Quick delivery, usually within 10-14 working days

- Made to order, no costs for excess steel or cutting

- Free and easy to operate

- Low maintenance

- Braking device to control slewing speed

- Lubrication-free acetyl bearings are used on a majority of jib arms

- Base fabricated directly to pillar and therefore expensive foundation frames are not required

CLIMBING CRANES

The Climbing Crane system is unique to NIKO Ltd. These systems were developed for the timber industry for lifting and handling large timber roof trusses. They are an ideal lifting solution for buildings with headroom space issues. Climbing cranes are usually radio-controlled for operator ease.

Chain Drive Climbing Crane

The climbing crane system is designed to clip directly to a sloping roof beam (up to a 15-degree angle). It utilizes standard NIKO Ltd parts with a fixed chain drive designed specifically for this application.

FESTOON CABLE SYSTEM

NIKO-Track uses a C-track festoon assembly and c-track festoon pendant system for overhead cranes and industrial machinery. All festoon trolleys can be modified to fit either flat cable or round hose. Our nylon cable trolleys are extremely reliable and smooth running. Because of the self-aligning tapered track, trolleys can never slide out of the center of the rail, ensuring a smooth and free operation.