NIKO Conveyors

Overhead Conveyors

Our overhead monorail conveyor systems are designed to suit most existing working environments. They can be configured as chain powered or a low-cost alternative to ‘power and free’ systems for certain scenarios such as lean manufacturing systems. Automatic switches allow for side shifting on dual tracks to maximize storage space. NIKO Conveyors’ six profiles are capable of carrying loads up to 3,520 lbs, providing a complete range of track sections, support fittings, trolleys, turns, and switches. These components can be assembled to produce a large range of modular design products including:

- Manual Overhead Conveyors

- Suspension Systems

- Festoon Cable Supply Systems

- Industrial Barn Door tracks and fittings

- Lightweight Overhead Cranes

NIKO Conveyors produces manual overhead conveyor and monorail transfer systems that are modular in design for ease of installation and modification.

KEY FEATURES

- Capacity: Up to 4,410 lbs.

- Multiple track sizes, profiles 21-27.000

- All components are electro galvanized for complete protection

- Zinc plated or Stainless steel 304/316

- Manual or powered conveyor equipment

- Flexible and simple track mounting system

- Standard components to connect and suspend the monorail conveyor track

- Seamless integration with NIKO Conveyors lightweight crane and lifting equipment

SUITABLE FOR

- Powder coating, painting, and material finishing applications

- Any industrial process that requires movement of parts, above floor level

- Situations where flightbars are used to move parts between processes within a plant

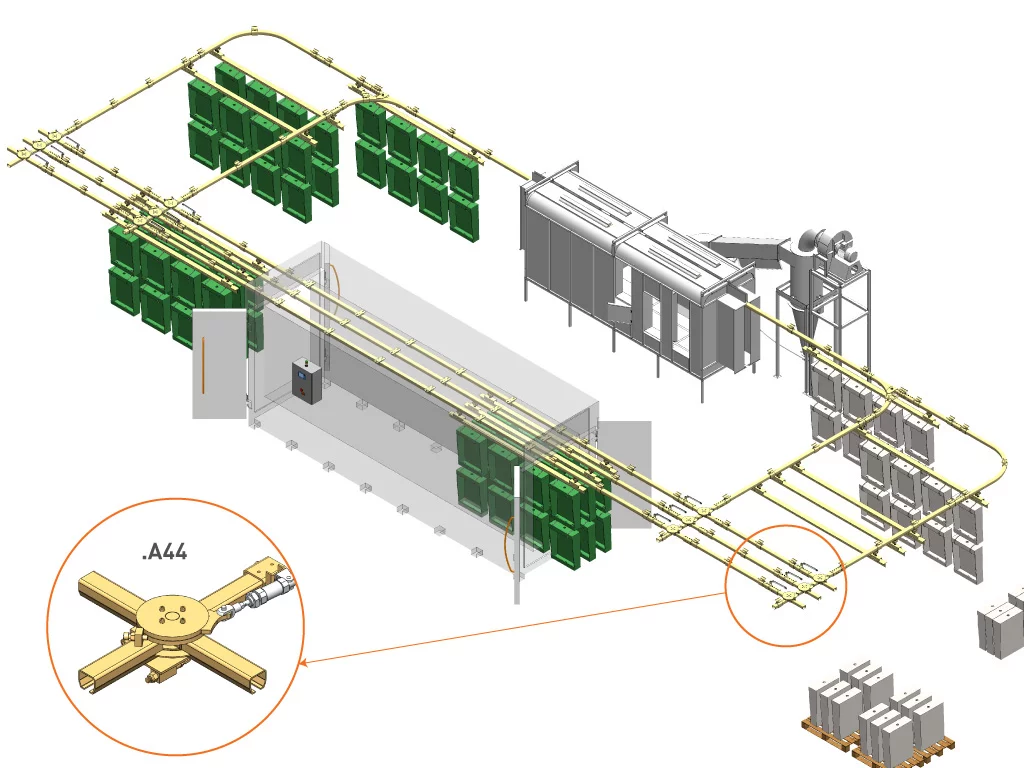

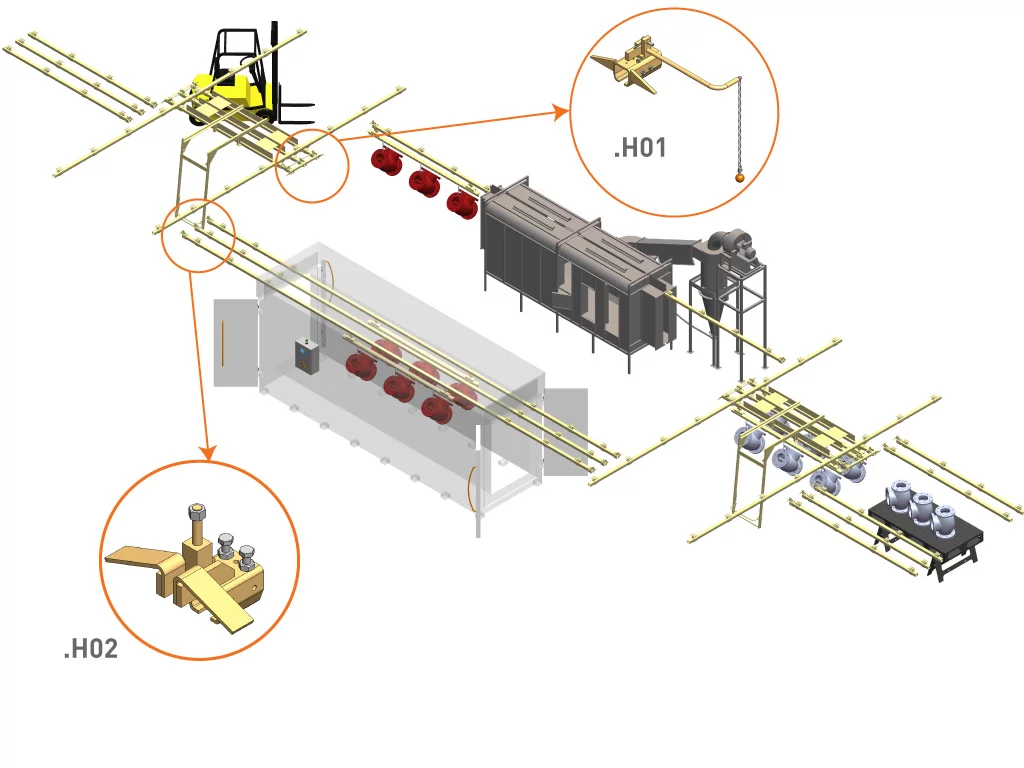

LOCALIZED POWERED TRAVEL

As an alternative to fully powered overhead conveyors, NIKO Conveyors offer a semi-automatic alternative. This system utilizes any manual conveyor system and powers it through ovens, spray booths, or any area where manual operation is not practical. This solution is far more cost-effective than using fully automatic conveyors. A chain conveyor can be installed parallel to the conveyor carrying the load in order to power the movement.

Powered movement can be achieved not only in straight lines but also around bends, making it possible to have a completely powered system.

Typical applications would be to power the movement through the ovens or painting booths and have the parking areas free in order to load and unload the products in adequate time. The benefits of the power chain conveyor are its competitive price, quiet operation, and the fact that it can be added to a manual conveyor at a future stage.

TRACK CONFIGURATION EXAMPLES

There are an infinite number of possible track layouts, to suit any particular application. NIKO Conveyors provides a wide range of turns, switches, and turntables, which can be manually or pneumatically operated. Layouts can be optimized for:

- Storage Space Utilization

- The use of automatic switches and a precision bent 90-degree track allows for a flight bar traveling along the manual overhead conveyor track, to be side shifted, and stored in an accumulating idle area for storage or process dwell time. The Overhead Conveyor Systems C1 catalog displays the different modular fittings to achieve precise track placement for maximum space utilization.

- Overhead Load Positioning

- The enclosed precision track has tapered sides to ensure that the load-carrying trolleys self locate to run freely and smoothly with minimal force required to move the loaded trolley. Repeatable positioning of loaded trolleys is achieved throughout the entire manual overhead conveyor system.

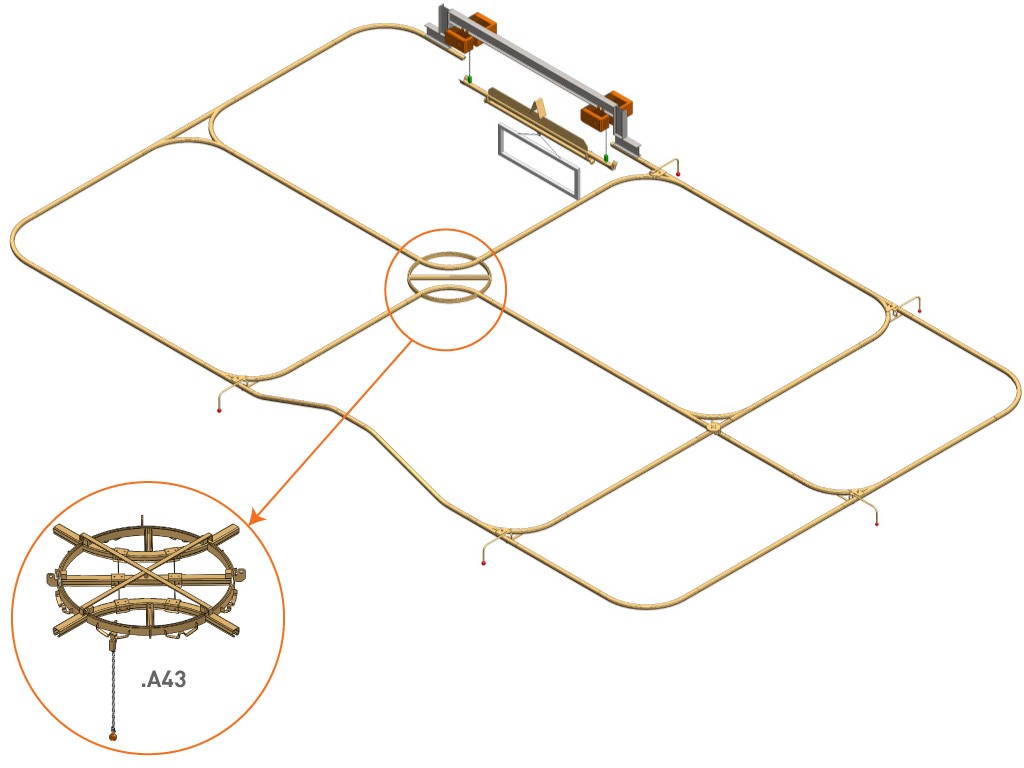

- NIKO Conveyors Overhead Turntable Detour System

- The unique NIKO Conveyors Turntable Detour system allows for multiple overhead track systems to be interconnected. Loads of flight bars are easily transferred between different processes or areas of the plant. Turntables are an ergonomic solution to multiple conveyor destination systems, reducing capital expenditure on more complex overhead conveyor track layouts.

-

- Manual Overhead Conveyor with Pneumatic Turntables

-

- Manual Overhead System with Crane Wagon

-

- Overhead Conveyor with Multiple Turn Table Switch