Revolutionize Your Paint and Powder Surface Treatment Process

Since 1972, NIKO has been at the forefront of manufacturing high-quality conveyors and value-added solutions for painting lines. With our expertise in manual overhead conveyors and a commitment to innovation, we offer modular and flexible designs that elevate your production capabilities.

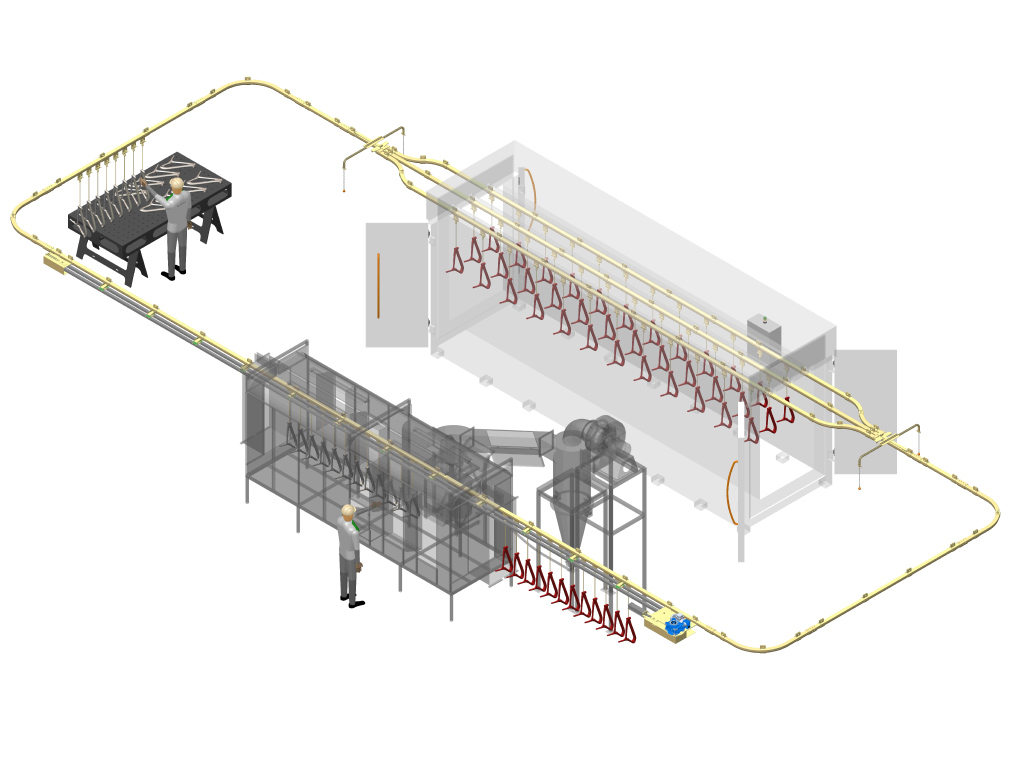

Manual Overhead Conveyor Systems: Our manual overhead conveyors are designed with your needs in mind. Featuring self-cleaning enclosed track profiles and maintenance-free bearings, these systems ensure long life and low maintenance. Easily extend or relocate the system to adapt to changing requirements, and seamlessly upgrade existing manual conveyors to power solutions with minimal conversion time. Experience smooth and easy movement of loads, ideal for powder or liquid coating systems.

Explore Our Range of Solutions:

1. Manual Overhead Conveyor with Crane Wagon

- Affordable and efficient solution

- Optimal space utilization inside the oven

- Ergonomically designed crane wagons for easier load handling

- Option for electric crane wagon for enhanced automation

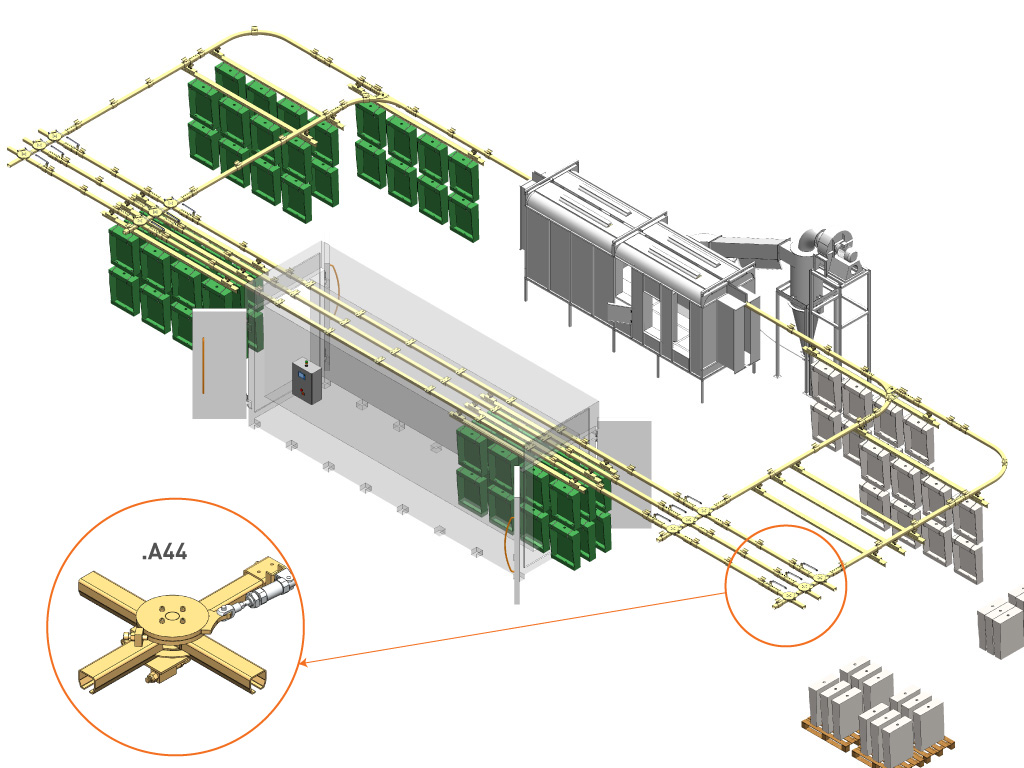

2. Manual Overhead Conveyor with Pneumatic Turntables

- Utilize minimum space with pneumatic turntables

- Cost-effective solution without compromising quality

- Optimal space utilization inside the oven

- Option for power side transfer through the paint booth for increased efficiency

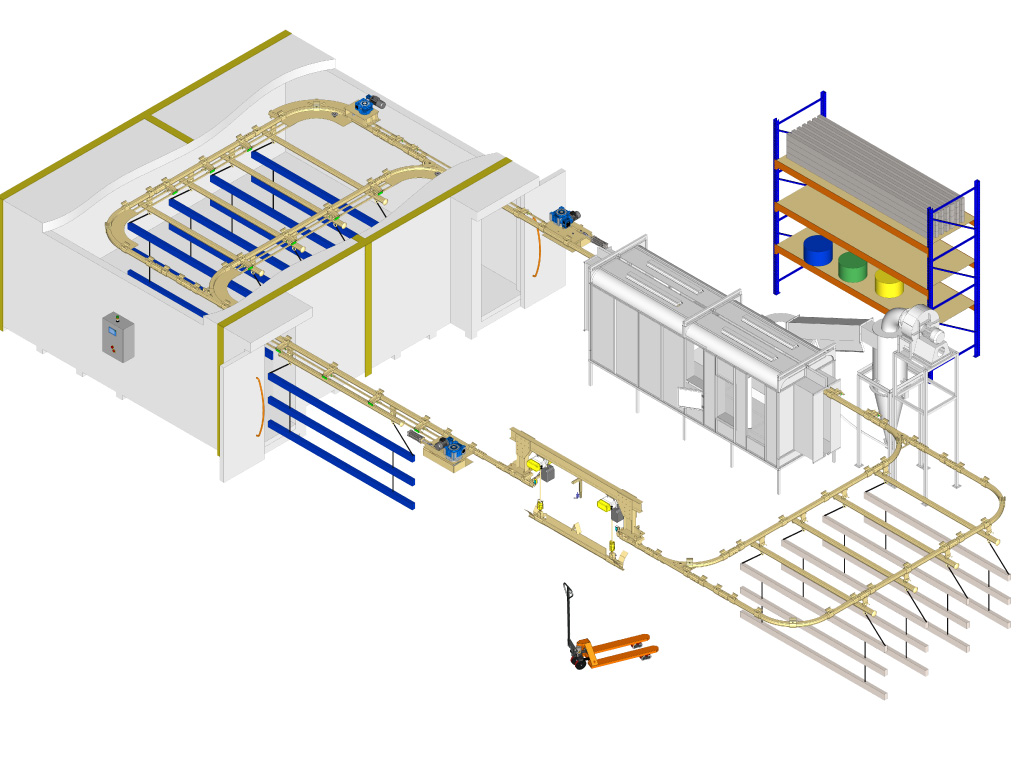

3. Manual Overhead Conveyor with Swivel Switches

- Achieve high productivity with mechanically automatic switches

- Optimal space usage inside the oven

- Ergonomic load transfer in multiple directions with swivel switches available in pulling chain or automatic configurations

4. Power Chain Conveyors

- Power the sections that matter most for increased efficiency

- Reduce labor costs with automatic flight bar transportation in consecutive stages

- Energy-saving compared to fully automated systems, ensuring cost-effectiveness without sacrificing performance

5. Drop Lift Unit

- Ergonomic station for loading/unloading with adjustable load height

- Maximum safe working load (SWL) of 1600kg

- Low headroom solution available for space-constrained environments

- Supplied as a complete kit for easy installation and operation

6. Fully Powered System with Crane Wagons

- Harness the power of a fully automated system with power chain and wagon driven by power-driven trolley

- Experience high productivity and reduced labor costs

- Automatic connection between crane wagon lines and conveyor for seamless operation

Experience Excellence with NIKO Conveyors: Benefit from our engineering consultation support and project management expertise as we work with you to find the best solution for your paint and powder surface treatment needs. Trust NIKO Conveyors to revolutionize your production line and maximize efficiency. Contact us today to learn more about how we can elevate your operations.